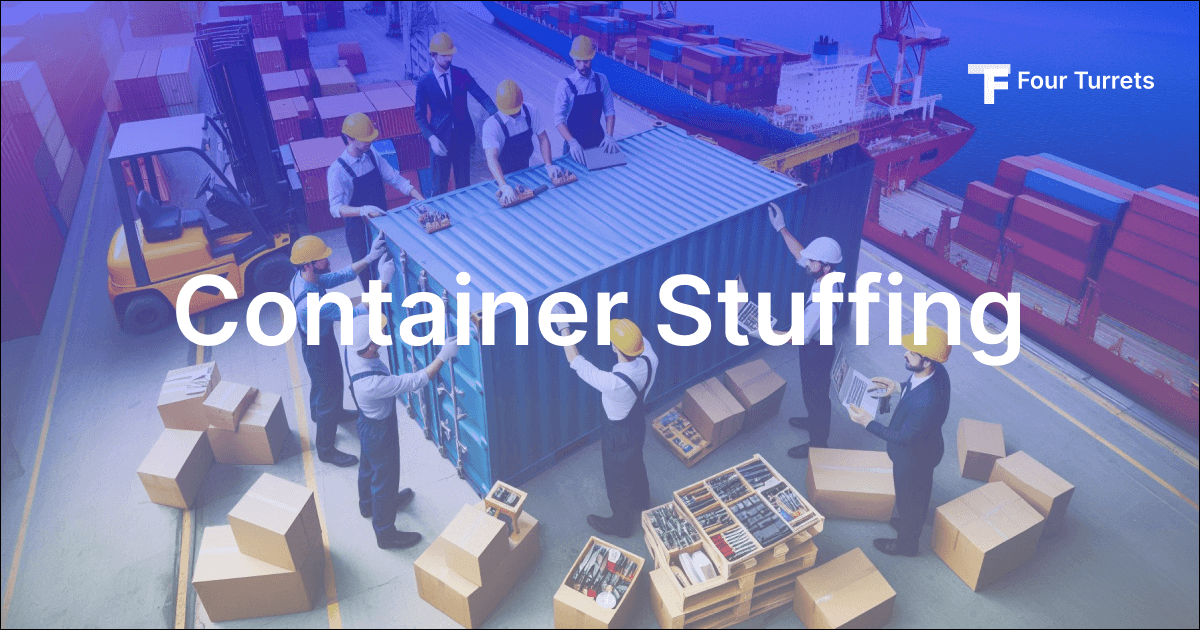

What is stuffing in shipping?

Stuffing is the process of loading goods in a container. A shipper will load the container as per demand from the consignee. Depending on the order and the volume of the goods, a Full-Container Load or Less-than Container Load will be stuffed.

The container is generally de-stuffed or devanning at the destination. Generally, shipping containers are de-stuffed at the consignee’s or logistic provider’s warehouse.

Container stuffing and de-stuffing: How it’s done?

In the ever-evolving shipping industry, cargo stuffing and devanning are pivotal to the successful movement of cargo across the globe. The term “stuffing” in the shipping industry refers to loading goods into a container, while “de-stuffing” or “stripping” refers to unloading cargo from a container. When it comes to international shipping, these processes are critical to maintaining the integrity of the shipment and ensuring timely delivery. Various tools such as forklifts and cranes are employed to manage the loading and unloading processes carefully. The type of container being loaded, whether it’s a reefer or a standard container, dictates specific handling and storage procedures.

One common scenario in the shipping and logistics field is container vanning, which means stuffing a container with freight. This can involve varying load sizes, from vast less-than-container load (LCL) shipments to full container loads. Cross docking facilitates rapid transfer, minimizing warehousing times by moving containers onto their next transport stage swiftly. During the process, items like pallets and crates may be used to stack and organize cargo within the container, optimizing space and ensuring safety.

Once the shipment arrives at its destination, the ultimate guide to container de-stuffing ensures that goods are efficiently unloaded. This process is vital to maintaining supply chain efficiency and customer satisfaction. On forums like Quora, logistics professionals often exchange insights and best practices for both stuffing and de-stuffing. Whether importing or exporting, proper handling of these tasks not only ensures the preservation of cargo but also the seamless flow of logistics operations.

Types of Stuffing Techniques

Each shipment has its requirements, so the packaging must be tailored accordingly. Depending on the nature of the goods and the means of transportation, here are the most appropriate techniques for loading cargo into containers.

Goods in cardboard cartons: Storing goods in cardboard cartons is the easiest, yet powerful way to manage shipping container stuffing. Similar-sized cartons will make it stack layers and provide durability, shock absorption, and flexibility to stuff the container. Cardboard cartons can be used to store a variety of products from food items to industrial supplies.

Using sacks and bags: Bigger bags and sacks are an easy solution to store and manage smaller products such as grains, dried fruits, and more. They provide relatively lesser protection. But, using dividers between them will save damage from chafing.

Drum storage: Using drums to store goods is ideal for chemical and bulk liquids. Steel or HDPE drums are used to transport various items including chemicals, food, fuel, liquids, and more. These cylindrical shaped drums often offer rigidity, durability, and sustainability.

Goods on pallets: Pallets are typically made from wood, plastic, and sometimes metals. They provide an easy solution for transporting in and out of containers with the help of forklifts. Their higher loading capacity and having a little elevated design from the floor help the goods stay moisture-free as well.

Wooden boxes and crates: Being made up of wood, they offer lightweight function with strength. Goods stored on pallets are useful for machinery, electronic gadgets, and other goods.

Types of Possible Damages to Cargo

Various elements play a role in damaging cargo during the loading or transit process. Improper handling of packages and machinery, excessive loading, poor management of temperature and humidity, and carelessness due to taking shortcuts while loading are some of the primary contributors.

Physical damage, wet/moisture damage, contamination through other cargo, infested cargo, and reefer damage to cargo are some of the most common damages taking place in transit.

De-Stuffing of cargo containers

The containerization procedure concludes once the goods have been safely transported and the shipment is offloaded. Appropriate measures must be implemented to avert any damage to the cargo during the unloading phase and while transferring the goods to the receiving client.

- Check and verify your shipment details, and container number mentioned in the documents.

- Investigate the container for any sign of visible external damages including breakage or leakage. If there are, make a detailed note of it.

- Open the container and let it ventilate for a few minutes to let odors away.

- Cross-check if every single package has been unloaded or not.

- Once all the goods are de-stuffed, make sure to clean the container by removing all the residue and packaging materials in it for subsequent use.

- Remove labels and markings for the next users.

The success of shipping and a great supply chain efficiency depends on how well the goods were loaded and how minimal to no damage has been made to the goods being supplied. Work with Four Turrets to scale your international business.